產(chǎn)品中心

美國(guó)強(qiáng)鹿柴油機(jī)維修配件技術(shù)中心

約翰迪爾John Deere柴油機(jī)配件 美國(guó)麥克福斯

卡特彼勒柴油發(fā)動(dòng)機(jī)參數(shù)

沃爾沃發(fā)動(dòng)機(jī)全系參數(shù)

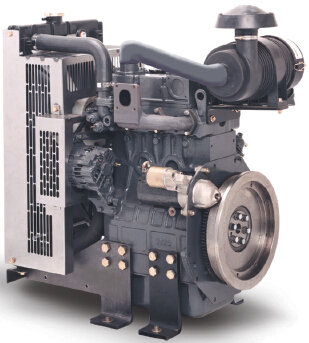

英國(guó)珀金斯原廠配件

珀金斯柴油機(jī)技術(shù)中心

珀金斯發(fā)動(dòng)機(jī)零件查詢(xún)圖冊(cè)

日本三菱柴油機(jī)發(fā)電機(jī)配件

德國(guó)道依茨 韓國(guó)大宇柴油發(fā)動(dòng)機(jī)配件

康明斯全系列柴油發(fā)動(dòng)機(jī)

沃爾沃 MTU 原廠配件銷(xiāo)售中心

瑞典沃爾沃遍達(dá)原裝柴油機(jī)配件

康明斯維修技術(shù)中心

卡特彼勒柴油發(fā)動(dòng)機(jī)原廠配件銷(xiāo)售中心

品牌柴油發(fā)電機(jī)組

康明斯柴油發(fā)動(dòng)機(jī)配件中心

珀金斯402/403F-11操作保養(yǎng)(英文)二

詳細(xì)描述

Buildup – Compounds, elements, corrosive

chemicals, and salt can damage some components.

Altitude – Problems can arise when the engine is

operated at altitudes that are higher than the intended

settings for that application. Necessary adjustments

should be made.

Incorrect Operating Procedures

• Extended operation at low idle

• Frequent hot shutdowns

• Operating at excessive loads

• Operating at excessive speeds

• Operating outside the intended application

Incorrect Maintenance Procedures

• Extending the maintenance intervals

• Failure to use recommended fuel, lubricants, and

coolant/antifreeze

This document is printed from SPI². Not for RESALE

![]()

54

SEBU9064

Maintenance Recommendations

Maintenance Interval Schedule

i05335244

“Engine Air Cleaner Element (Single Element) -

Inspect/Clean/Replace”...........................................66

“Engine Oil and Filter - Change”..............................69

“Hoses and Clamps - Inspect/Replace”...................78

“Radiator - Clean” ....................................................79

MaintenanceInterval Schedule

When Required

“Battery - Replace”...................................................57

“Engine - Clean”.......................................................64

Every 1000 Service Hours

“Alternator and Fan Belts - Replace”.......................56

“Engine Valve Lash - Check”...................................71

“Engine Air Cleaner Element (Dual Element) -

Inspect/Clean/Replace”...........................................64

Every 2000 Service Hours

“Engine Air Cleaner Element (Single Element) -

Inspect/Clean/Replace”...........................................66

“Alternator - Inspect”................................................54

“Engine Crankcase Breather - Replace” .................68

“Engine Mounts - Inspect” .......................................68

“Starting Motor - Inspect”.........................................80

“Fuel System - Prime”..............................................74

Daily

“Coolant Level - Check”...........................................61

“Driven Equipment - Check” ....................................63

“Engine Air Cleaner Service Indicator - Inspect”.....67

“Engine Air Precleaner - Check/Clean”...................67

“Engine Oil Level - Check”.......................................68

Every 3000 Service Hours

“Coolant Temperature Regulator - Replace” ...........62

“Fuel Injector - Test/Change”...................................73

“Water Pump - Inspect”............................................81

“Fuel System Primary Filter/Water Separator -

Drain”.......................................................................75

Every 3000 Service Hours or 2

Years

“Walk-Around Inspection”........................................80

“Coolant (Commercial Heavy-Duty) - Change” .......58

Every 50 Service Hours or Weekly

Every 12 000 Service Hours or 6

Years

“Fuel Tank Water and Sediment - Drain”.................78

Every 250 Service Hours or 6

Months

“Coolant (ELC) - Change”........................................59

Commissioning

“Alternator and Fan Belts - Inspect/Adjust” .............55

“Fan Clearance - Check” .........................................72

Every 500 Service Hours

“Fan Clearance - Check” .........................................72

“Fuel Filter (In-Line) - Replace”................................72

“Fuel System Primary Filter - Replace” ...................74

“Fuel System Secondary Filter - Replace” ..............76

i02322311

Alternator - Inspect

Perkins recommends a scheduled inspection of the

alternator. Inspect the alternator for loose

connections and correct battery charging. Check the

ammeter (if equipped) during engine operation in

order to ensure correct battery performance and/or

correct performance of the electrical system. Make

repairs, as required.

Every 500 Service Hours or 1 Year

“Battery Electrolyte Level - Check”..........................57

“Cooling System Supplemental Coolant Additive

(SCA) - Test/Add”.....................................................63

“Engine Air Cleaner Element (Dual Element) -

Inspect/Clean/Replace”...........................................64

This document is printed from SPI². Not for RESALE

![]()

SEBU9064

55

Maintenance Recommendations

Alternator and Fan Belts - Inspect/Adjust

Check the alternator and the battery charger for

correct operation. If the batteries are correctly

charged, the ammeter reading should be very near

zero. All batteries should be kept charged. The

batteries should be kept warm because temperature

affects the cranking power. If the battery is too cold,

the battery will not crank the engine. When the engine

is not run for long periods of time or if the engine is

run for short periods, the batteries may not fully

charge. A battery with a low charge will freeze more

easily than a battery with a full charge.

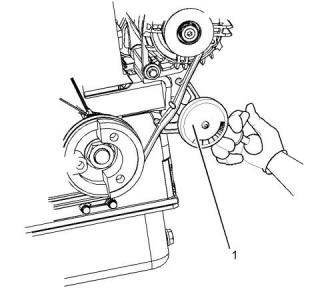

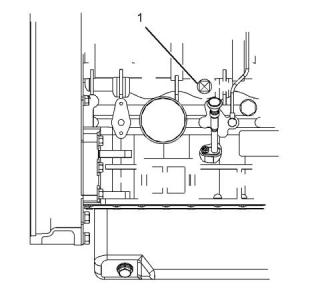

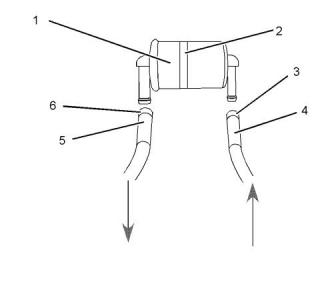

Install the gauge (1) at the center of the belt between

the alternator and the crankshaft pulley and check the

belt tension. The correct tension for a new belt is

400 N (90 lb) to 489 N (110 lb). The correct tension

for a used belt that has been in operation for 30

minutes or more at the rated speed is 267 N (60 lb) to

356 N (80 lb).

If twin belts are installed, check and adjust the

tension on both belts.

Adjustment

i05341153

Alternator and Fan Belts -

Inspect/Adjust

Inspection

To maximize the engine performance, inspect the

belts for wear and for cracking. Replace belts that are

worn or damaged.

For applications that require multiple drive belts,

replace the belts in matched sets. Replacing only one

belt of a matched set will cause the new belt to carry

more load because the older belt is stretched. The

additional load on the new belt could cause the new

belt to break.

If the belts are too loose, vibration causes

unnecessary wear on the belts and pulleys. Loose

belts may slip enough to cause overheating.

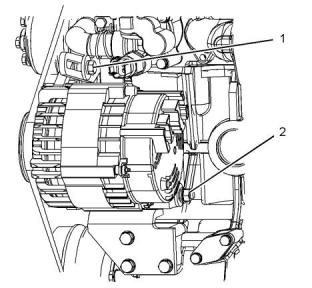

Illustration 25

g03383151

To check accurately the belt tension, a suitable gauge

should be used.

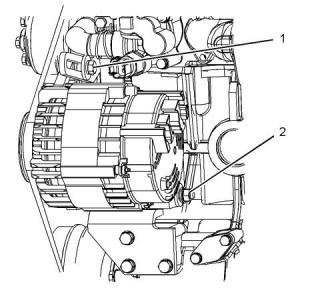

Illustration 26

g03383155

Illustration 24

g03383147

Typical example

(1) Burroughs Gauge

1. Loosen adjusting bolt (1) and mounting bolt and

nut (2). Loosen bolt (3).

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

56

SEBU9064

Maintenance Recommendations

Alternator and Fan Belts - Replace

2. Move the alternator in order to increase or

decrease the belt tension.

3. Tighten adjusting bolt (1) and tighten mounting

bolts and nut (2). Tighten bolt (3). Tighten all fixing

to a torque of 25 N·m (221 lb in)

i05341723

Alternator and Fan Belts -

Replace

For applications that require multiple drive belts,

replace the belts in matched sets. Replacing only one

belt of a matched set will cause the new belt to carry

more load because the older belt is stretched. The

additional load on the new belt could cause the new

belt to break.

Note: When new belts are installed, check the belt

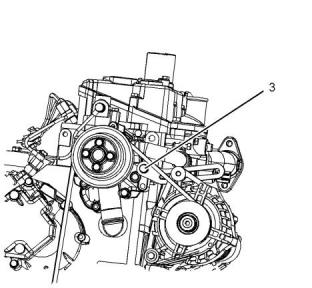

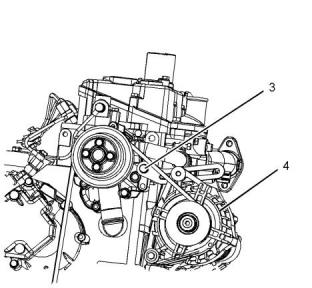

Illustration 28

g03383666

tension again after 20 hours of engine operation.

Typical example

Removal and InstallationProcedure

1. Loosen adjusting bolt (1) and mounting bolt and

nut (2). Loosen bolt (3).

Refer to the original equipment manufacture for

removal and installation of the fan guards.

2. Push the alternator (4) towards the engine.

Note: If the belt is to be reused, mark the belt in order

to show direction of rotation.

Illustration 27

g03383665

Typical example

Illustration 29

g03383667

Typical example

3. Remove the belt (5).

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

SEBU9064

57

Maintenance Recommendations

Battery - Replace

4. Install new belt (5) and adjust the alternator to the

required tension.

Note: Always recycle a battery. Never discard a

battery. Dispose of used batteries to an appropriate

recycling facility.

5. Tighten bolt (1) and tighten bolt and nut (2). Tighten

bolt (3). Tighten all bolts and nuts to a torque of

25 N·m (221 lb in).

5. Remove the used battery.

6. Install the new battery.

Refer to this Operation and Maintenance Manual,

“Alternator and Fan Belts - Inspect/Adjust” for the

tension of the belt.

Note: Before the cables are connected, ensure that

the engine start switch is OFF.

7. Connect the cable from the starting motor to the

POSITIVE “+” battery terminal.

i02322315

Battery - Replace

8. Connect the NEGATIVE “-” cable to the

NEGATIVE “-” battery terminal.

i02747977

Battery Electrolyte Level -

Check

Batteries give off combustible gases which can

explode. A spark can cause the combustible

gases to ignite. This can result in severe personal

injury or death.

When the engine is not run for long periods of time or

when the engine is run for short periods, the batteries

may not fully recharge. Ensure a full charge in order

to help prevent the battery from freezing. If batteries

are correctly charged, the ammeter reading should be

very near zero, when the engine is in operation.

Ensure proper ventilation for batteries that are in

an enclosure. Follow the proper procedures in or-

der to help prevent electrical arcs and/or sparks

near batteries. Do not smoke when batteries are

serviced.

All lead-acid batteries contain sulfuric acid which

can burn the skin and clothing. Always wear a

face shield and protective clothing when working

on or near batteries.

The battery cables or the batteries should not be

removed with the battery cover in place. The bat-

tery cover should be removed before any servic-

ing is attempted.

Removing the battery cables or the batteries with

the cover in place may cause a battery explosion

resulting in personal injury.

1. Remove the filler caps. Maintain the electrolyte

level to the “FULL” mark on the battery.

If the addition of water is necessary, use distilled

water. If distilled water is not available use clean

water that is low in minerals. Do not use artificially

softened water.

1. Switch the engine to the OFF position. Remove all

electrical loads.

2. Turn off any battery chargers. Disconnect any

battery chargers.

2. Check the condition of the electrolyte with a

suitable battery tester.

3. The NEGATIVE “-” cable connects the NEGATIVE

“-” battery terminal to the NEGATIVE “-” terminal

on the starting motor. Disconnect the cable from

the NEGATIVE “-” battery terminal.

3. Install the caps.

4. Keep the batteries clean.

Clean the battery case with one of the following

cleaning solutions:

4. The POSITIVE “+” cable connects the POSITIVE

“+” battery terminal to the POSITIVE “+” terminal

on the starting motor. Disconnect the cable from

the POSITIVE “+” battery terminal.

• Use a solution of 0.1 kg (0.2 lb) baking soda

and 1 L (1 qt) of clean water.

• Use a solution of ammonium hydroxide .

Thoroughly rinse the battery case with clean water.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

58

SEBU9064

Maintenance Recommendations

Coolant (Commercial Heavy-Duty) - Change

i05336023

1. Stop the engine and allow the engine to cool.

Loosen the cooling system filler cap slowly in order

to relieve any pressure. Remove the cooling

system filler cap.

Coolant (Commercial Heavy-

Duty) - Change

NOTICE

Care must be taken to ensure that fluids are con-

tained during performance of inspection, mainte-

nance, testing, adjusting and repair of the product. Be

prepared to collect the fluid with suitable containers

before opening any compartment or disassembling

any component containing fluids.

Dispose of all fluids according to Local regulations

and mandates.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

Clean the cooling system and flush the cooling

system before the recommended maintenance

interval if the following conditions exist:

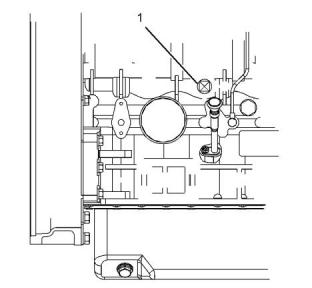

Illustration 30

g03380650

Typical example

• The engine overheats frequently.

• Foaming is observed.

2. Open the drain cock or remove the drain plug (1)

on the engine. Open the drain cock or remove the

drain plug on the radiator.

• The oil has entered the cooling system and the

coolant is contaminated.

Allow the coolant to drain.

• The fuel has entered the cooling system and the

coolant is contaminated.

NOTICE

Dispose of used engine coolant or recycle. Various

methods have been proposed to reclaim used coolant

for reuse in engine cooling systems. The full distilla-

tion procedure is the only method acceptable by Per-

kins to reclaim the coolant.

Note: When the cooling system is cleaned, only

clean water is needed.

Note: Inspect the water pump and the water

temperature regulator after the cooling system has

been drained. This is a good opportunity to replace

the water pump, the water temperature regulator, and

the hoses, if necessary.

For information regarding the disposal and the

recycling of used coolant, consult your Perkins

dealer or your Perkins distributor.

Drain

Flush

1. Flush the cooling system with clean water in order

to remove any debris.

Pressurized System: Hot coolant can cause seri-

ous burns. To open the cooling system filler cap,

stop the engine and wait until the cooling system

components are cool. Loosen the cooling system

pressure cap slowly in order to relieve the

pressure.

2. Close the drain cock or install the drain plug in the

engine. Close the drain cock or install the drain

plug on the radiator.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

SEBU9064

59

Maintenance Recommendations

Coolant (ELC) - Change

5. Clean the cooling system filler cap. Inspect the

gasket that is on the cooling system filler cap. If the

gasket that is on the cooling system filler cap is

damaged, discard the old cooling system filler cap

and install a new cooling system filler cap. If the

gasket that is on the cooling system filler cap is not

damaged, use a suitable pressurizing pump in

order to pressure test the cooling system filler cap.

The correct pressure for the cooling system filler

cap is stamped on the face of the cooling system

filler cap. If the cooling system filler cap does not

retain the correct pressure, install a new cooling

system filler cap.

NOTICE

Do not fill the cooling system faster than 5 L

(1.3 US gal) per minute to avoid air locks.

Cooling system air locks may result in engine

damage.

3. Fill the cooling system with clean water. Install the

cooling system filler cap.

4. Start and run the engine at low idle until the

temperature reaches 49 to 66 °C (120 to 150 °F).

5. Stop the engine and allow the engine to cool.

Loosen the cooling system filler cap slowly in order

to relieve any pressure. Remove the cooling

system filler cap. Open the drain cock or remove

the drain plug on the engine. Open the drain cock

or remove the drain plug on the radiator. Allow the

water to drain. Flush the cooling system with clean

water.

6. Start the engine. Inspect the cooling system for

leaks and for correct operating temperature.

i05336034

Coolant (ELC) - Change

Fill

NOTICE

1. Close the drain cock or install the drain plug on the

engine. Close the drain cock or install the drain

plug on the radiator.

Care must be taken to ensure that fluids are con-

tained during performance of inspection, mainte-

nance, testing, adjusting and repair of the product. Be

prepared to collect the fluid with suitable containers

before opening any compartment or disassembling

any component containing fluids.

NOTICE

Do not fill the cooling system faster than 5 L

(1.3 US gal) per minute to avoid air locks.

Dispose of all fluids according to Local regulations

and mandates.

Cooling system air locks may result in engine

damage.

NOTICE

Keep all parts clean from contaminants.

2. Fill the cooling system with Commercial Heavy-

Duty Coolant. Add Supplemental Coolant Additive

to the coolant. For the correct amount, refer to the

Operation and Maintenance Manual, “Fluid

Recommendations” topic (Maintenance Section)

for more information on cooling system

specifications. Do not install the cooling system

filler cap.

Contaminants may cause rapid wear and shortened

component life.

Clean the cooling system and flush the cooling

system before the recommended maintenance

interval if the following conditions exist:

• The engine overheats frequently.

• Foaming is observed.

3. Start and run the engine at low idle. Increase the

engine rpm to high idle. Run the engine at high idle

for 1 minute in order to purge the air from the

cavities of the engine block. Stop the engine.

• The oil has entered the cooling system and the

coolant is contaminated.

4. Check the coolant level. Maintain the coolant level

within 13 mm (0.5 inch) below the bottom of the

pipe for filling. Maintain the coolant level in the

expansion bottle (if equipped) at the correct level.

• The fuel has entered the cooling system and the

coolant is contaminated.

Note: When the cooling system is cleaned, only

clean water is needed when the ELC is drained and

replaced.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

60

SEBU9064

Maintenance Recommendations

Coolant (ELC) - Change

Note: Inspect the water pump and the water

temperature regulator after the cooling system has

been drained. This is a good opportunity to replace

the water pump, the water temperature regulator, and

the hoses, if necessary.

For information regarding the disposal and the

recycling of used coolant, consult your Perkins

dealer or your Perkins distributor.

Flush

Drain

1. Flush the cooling system with clean water in order

to remove any debris.

2. Close the drain cock or install the drain plug in the

engine. Close the drain cock or install the drain

plug on the radiator.

Pressurized System: Hot coolant can cause seri-

ous burns. To open the cooling system filler cap,

stop the engine and wait until the cooling system

components are cool. Loosen the cooling system

pressure cap slowly in order to relieve the

pressure.

NOTICE

Do not fill the cooling system faster than 5 L

(1.3 US gal) per minute to avoid air locks.

Cooling system air locks may result in engine

damage.

1. Stop the engine and allow the engine to cool.

Loosen the cooling system filler cap slowly in order

to relieve any pressure. Remove the cooling

system filler cap.

3. Fill the cooling system with clean water. Install the

cooling system filler cap.

4. Start and run the engine at low idle until the

temperature reaches 49 to 66 °C (120 to 150 °F).

5. Stop the engine and allow the engine to cool.

Loosen the cooling system filler cap slowly in order

to relieve any pressure. Remove the cooling

system filler cap. Open the drain cock or remove

the drain plug on the engine. Open the drain cock

or remove the drain plug on the radiator. Allow the

water to drain. Flush the cooling system with clean

water.

Fill

1. Close the drain cock or install the drain plug on the

engine. Close the drain cock or install the drain

plug on the radiator.

NOTICE

Do not fill the cooling system faster than 5 L

(1.3 US gal) per minute to avoid air locks.

Illustration 31

g03380650

Typical example

Cooling system air locks may result in engine

damage.

2. Open the drain cock or remove the drain plug (1)

on the engine. Open the drain cock or remove the

drain plug on the radiator.

2. Fill the cooling system with Extended Life Coolant

(ELC). Refer to the Operation and Maintenance

Manual, “Fluid Recommendations” topic

(Maintenance Section) for more information on

cooling system specifications. Do not install the

cooling system filler cap.

Allow the coolant to drain.

NOTICE

Dispose of used engine coolant or recycle. Various

methods have been proposed to reclaim used coolant

for reuse in engine cooling systems. The full distilla-

tion procedure is the only method acceptable by Per-

kins to reclaim the coolant.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

SEBU9064

61

Maintenance Recommendations

Coolant Level - Check

3. Start and run the engine at low idle. Increase the

engine rpm to high idle. Run the engine at high idle

for 1 minute in order to purge the air from the

cavities of the engine block. Stop the engine.

Pressurized System: Hot coolant can cause seri-

ous burns. To open the cooling system filler cap,

stop the engine and wait until the cooling system

components are cool. Loosen the cooling system

pressure cap slowly in order to relieve the

pressure.

4. Check the coolant level. Maintain the coolant level

within 13 mm (0.5 inch) below the bottom of the

pipe for filling. Maintain the coolant level in the

expansion bottle (if equipped) at the correct level.

2. Loosen filler cap slowly in order to relieve any

pressure. Remove the filler cap.

5. Clean the cooling system filler cap. Inspect the

gasket that is on the cooling system filler cap. If the

gasket that is on the cooling system filler cap is

damaged, discard the old cooling system filler cap

and install a new cooling system filler cap. If the

gasket that is on the cooling system filler cap is not

damaged, use a suitable pressurizing pump in

order to pressure test the cooling system filler cap.

The correct pressure for the cooling system filler

cap is stamped on the face of the cooling system

filler cap. If the cooling system filler cap does not

retain the correct pressure, install a new cooling

system filler cap.

3. Pour the correct coolant mixture into the tank.

Refer to the Operation and Maintenance Manual,

“Refill Capacities and Recommendations” for

information on the correct mixture and type of

coolant. Refer to the Operation and Maintenance

Manual, “Refill Capacities and Recommendations”

for the engine cooling system capacity. Do not fill

the coolant recovery tank above “COLD FULL”

mark.

6. Start the engine. Inspect the cooling system for

leaks and for correct operating temperature.

i05149389

Coolant Level - Check

Engines With a Coolant Recovery

Tank

Note: The cooling system may not have been

provided by Perkins . The procedure that follows is

for typical cooling systems. Refer to the OEM

information for the correct procedures.

Check the coolant level when the engine is stopped

and cool.

Illustration 32

g02590196

NOTICE

Filler cap

When any servicing or repair of the engine cooling

system is performed, the procedure must be per-

formed with the engine on level ground. Level ground

will allow you to check accurately the coolant level.

This checking will also help in avoiding the risk of in-

troducing an air lock into the coolant system.

4. Clean the filler cap and the receptacle. Reinstall

the filler cap and inspect the cooling system for

leaks.

Note: The coolant will expand as the coolant heats

up during normal engine operation. The additional

volume will be forced into the coolant recovery tank

during engine operation. When the engine is stopped

and cool, the coolant will return to the engine.

1. Observe the coolant level in the coolant recovery

tank. Maintain the coolant level to “COLD FULL”

mark on the coolant recovery tank.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

62

SEBU9064

Maintenance Recommendations

Coolant Temperature Regulator - Replace

Engines Without a Coolant

Recovery Tank

i05160120

Coolant Temperature

Regulator - Replace

Check the coolant level when the engine is stopped

and cool.

Replace the water temperature regulator before the

water temperature regulator fails. This is a

recommended preventive maintenance practice.

Replacing the water temperature regulator reduces

the chances for unscheduled downtime.

A water temperature regulator that fails in a partially

opened position can cause overheating or

overcooling of the engine.

A water temperature regulator that fails in the closed

position can cause excessive overheating. Excessive

overheating could result in cracking of the cylinder

head or piston seizure problems.

Illustration 33

g00285520

A water temperature regulator that fails in the open

position will cause the engine operating temperature

to be too low during partial load operation. Low

engine operating temperatures during partial loads

could cause an excessive carbon buildup inside the

cylinders. This excessive carbon buildup could result

in an accelerated wear of the piston rings and wear of

the cylinder liner.

Cooling system filler cap

Pressurized System: Hot coolant can cause seri-

ous burns. To open the cooling system filler cap,

stop the engine and wait until the cooling system

components are cool. Loosen the cooling system

pressure cap slowly in order to relieve the

pressure.

NOTICE

Failure to replace your water temperature regulator

on a regularly scheduled basis could cause severe

engine damage.

1. Remove the cooling system filler cap slowly in

order to relieve pressure.

Perkins engines incorporate a shunt design cooling

system and require operating the engine with a water

temperature regulator installed.

2. Maintain the coolant level at the maximum mark

that is correct for your application. If the engine is

equipped with a sight glass, maintain the coolant

level to the correct level in the sight glass.

If the water temperature regulator is installed incor-

rectly, the engine may overheat, causing cylinder

head damage. Ensure that the new water tempera-

ture regulator is installed in the original position. En-

sure that the water temperature regulator vent hole is

open.

3. Clean the cooling system filler cap and inspect the

gasket. If the gasket is damaged, discard the old

filler cap and install a new filler cap. If the gasket is

not damaged, use a suitable pressurizing pump in

order to pressure test the filler cap. The correct

pressure is stamped on the face of the filler cap. If

the filler cap does not retain the correct pressure,

install a new filler cap.

Do not use liquid gasket material on the gasket or cyl-

inder head surface.

Refer to the Disassembly and Assembly Manual,

“Water Temperature Regulator - Remove and Install”

for the replacement procedure of the water

temperature regulator, or consult your Perkins

dealer or your Perkins distributor.

4. Inspect the cooling system for leaks.

Note: If only the water temperature regulators are

replaced, drain the coolant from the cooling system to

a level that is below the water temperature regulator

housing.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

SEBU9064

63

Maintenance Recommendations

Cooling System Supplemental Coolant Additive (SCA) - Test/Add

i03644948

NOTICE

Cooling System Supplemental

Coolant Additive (SCA) - Test/

Add

When any servicing or repair of the engine cooling

system is performed the procedure must be per-

formed with the engine on level ground. This will allow

you to accurately check the coolant level. This will al-

so help in avoiding the risk of introducing an air lock

into the coolant system.

1. Slowly loosen the cooling system filler cap in order

to relieve the pressure. Remove the cooling

system filler cap.

Cooling system coolant additive contains alkali.

To help prevent personal injury, avoid contact

with the skin and the eyes. Do not drink cooling

system coolant additive.

Note: Always discard drained fluids according to local

regulations.

2. If necessary, drain some coolant from the cooling

system into a suitable container in order to allow

space for the extra SCA.

Test for SCA Concentration

Heavy-Duty Coolant/Antifreezeand SCA

3. Add the correct amount of SCA. Refer to the

Operation and Maintenance Manual, “Refill

Capacities and Recommendations” for more

information on SCA requirements.

NOTICE

Do not exceed the recommended six percent supple-

mental coolant additive concentration.

4. Clean the cooling system filler cap and inspect the

gasket. If the gasket is damaged, discard the old

filler cap and install a new filler cap. If the gasket is

not damaged, use a suitable pressurizing pump in

order to pressure test the filler cap. The correct

pressure is stamped on the face of the filler cap. If

the filler cap does not retain the correct pressure,

install a new filler cap.

Use a Coolant Conditioner Test Kit in order to check

the concentration of the SCA.

Add the SCA, If Necessary

NOTICE

Do not exceed the recommended amount of supple-

mental coolant additive concentration. Excessive sup-

plemental coolant additive concentration can form

deposits on the higher temperature surfaces of the

cooling system, reducing the engine's heat transfer

characteristics. Reduced heat transfer could cause

cracking of the cylinder head and other high tempera-

ture components. Excessive supplemental coolant

additive concentration could also result in radiator

tube blockage, overheating, and/or accelerated water

pump seal wear. Never use both liquid supplemental

coolant additive and the spin-on element (if equipped)

at the same time. The use of those additives together

could result in supplemental coolant additive concen-

tration exceeding the recommended maximum.

i02151646

Driven Equipment - Check

Refer to the OEM specifications for more information

on the following maintenance recommendations for

the driven equipment:

• Inspection

• Adjustment

• Lubrication

• Other maintenance recommendations

Perform any maintenance for the driven equipment

which is recommended by the OEM.

Pressurized System: Hot coolant can cause seri-

ous burns. To open the cooling system filler cap,

stop the engine and wait until the cooling system

components are cool. Loosen the cooling system

pressure cap slowly in order to relieve the

pressure.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

64

SEBU9064

Maintenance Recommendations

Engine - Clean

i05335960

i04150582

Engine - Clean

Engine Air Cleaner Element

(Dual Element) - Inspect/Clean/

Replace

Personal injury or death can result from high

voltage.

NOTICE

Never run the engine without an air cleaner element

installed. Never run the engine with a damaged air

cleaner element. Do not use air cleaner elements with

damaged pleats, gaskets or seals. Dirt entering the

engine causes premature wear and damage to en-

gine components. Air cleaner elements help to pre-

vent airborne debris from entering the air inlet.

Moisture

can

create

paths

of

electrical

conductivity.

Make sure that the electrical system is OFF. Lock

out the starting controls and tag the controls “DO

NOT OPERATE” .

NOTICE

Accumulated grease and oil on an engine is a fire

hazard. Keep the engine clean. Remove debris and

fluid spills whenever a significant quantity accumu-

lates on the engine.

NOTICE

Never service the air cleaner element with the engine

running since this will allow dirt to enter the engine.

Servicing the Air Cleaner Elements

Periodic cleaning of the engine is recommended.

Steam cleaning the engine will remove accumulated

oil and grease. A clean engine provides the following

benefits:

Note: The air filter system may not have been

provided by Perkins . The procedure that follows is

for a typical air filter system. Refer to the OEM

information for the correct procedure.

• Easy detection of fluid leaks

• Maximum heat transfer characteristics

• Ease of maintenance

If the air cleaner element becomes plugged, the air

can split the material of the air cleaner element.

Unfiltered air will drastically accelerate internal engine

wear. Refer to the OEM information for the correct air

cleaner elements for your application.

Note: Caution must be used in order to prevent

electrical components from being damaged by

excessive water when the engine is cleaned.

Pressure washers and steam cleaners should not be

directed at any electrical connectors or the junction of

cables into the rear of the connectors. Avoid electrical

components such as the alternator, the starter, and

the ECM. Protect the fuel injection pump from fluids in

order to wash the engine.

• Check the precleaner (if equipped) and the dust

bowl daily for accumulation of dirt and debris.

Remove any dirt and debris, as needed.

• Operating in dirty conditions may require more

frequent service of the air cleaner element.

• The air cleaner element should be replaced at

least one time per year. This replacement should

be performed regardless of the number of

cleanings.

Replace the dirty air cleaner elements with clean air

cleaner elements. Before installation, the air cleaner

elements should be thoroughly checked for tears and/

or holes in the filter material. Inspect the gasket or the

seal of the air cleaner element for damage. Maintain a

supply of suitable air cleaner elements for

replacement purposes.

Dual Element Air Cleaners

The dual element air cleaner contains a primary air

cleaner element and a secondary air cleaner

element.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

SEBU9064

65

Maintenance Recommendations

Engine Air Cleaner Element (Dual Element) - Inspect/Clean/Replace

The primary air cleaner element can be used up to six

times if the element is properly cleaned and properly

inspected. The primary air cleaner element should be

replaced at least one time per year. This replacement

should be performed regardless of the number of

cleanings.

Cleaning the Primary Air Cleaner

Elements

Refer to the OEM information in order to determine

the number of times that the primary filter element

can be cleaned. When the primary air cleaner

element is cleaned, check for rips or tears in the filter

material. The primary air cleaner element should be

replaced at least one time per year. This replacement

should be performed regardless of the number of

cleanings.

The secondary air cleaner element is not serviceable.

Refer to the OEM information for instructions in order

to replace the secondary air cleaner element.

When the engine is operating in environments that

are dusty or dirty, air cleaner elements may require

more frequent replacement.

NOTICE

Do not tap or strike the air cleaner element.

Do not wash the primary air cleaner element.

Use low pressure (207 kPa; 30 psi maximum) pres-

surized air or vacuum cleaning to clean the primary

air cleaner element.

Take extreme care in o, rder to avoid damage to the air

cleaner elements.

Do not use air cleaner elements that have damaged

pleats, gaskets, or seals.

Refer to the OEM information in order to determine

the number of times that the primary air cleaner

element can be cleaned. Do not clean the primary air

filter element more than three times. The primary air

cleaner element must be replaced at least one time

per year.

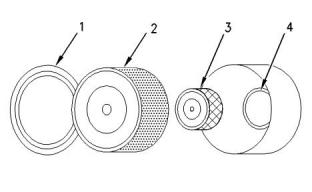

Illustration 34

g00736431

(1) Cover

(2) Primary air cleaner element

(3) Secondary air cleaner element

(4) Air inlet

Cleaning the air filter element will not extend the life

of the air filter element.

1. Remove the cover. Remove the primary air cleaner

element.

Visually inspect the primary air cleaner element

before cleaning. Inspect air cleaner elements for

damage to the pleats, the seals, the gaskets, and the

outer cover. Discard any damaged air cleaner

element.

2. The secondary air cleaner element should be

removed and discarded for every three cleanings

of the primary air cleaner element.

Two methods may be used in order to clean the

primary air cleaner element:

Note: Refer to “Cleaning the Primary Air Cleaner

Elements”.

• pressurized air

3. Cover the air inlet with tape in order to keep out

dirt.

• Vacuum cleaning

4. Clean the inside of the air cleaner cover and body

with a clean, dry cloth.

Pressurized Air

5. Remove the tape from the air inlet. Install the

secondary air cleaner element. Install a primary air

cleaner element that is new or cleaned.

Personal injury can result from air pressure.

Personal injury can result without following prop-

er procedure. When using pressure air, wear a

protective face shield and protective clothing.

6. Install the air cleaner cover.

7. Reset the air cleaner service indicator.

Maximum air pressure at the nozzle must be less

than 205 kPa (30 psi) for cleaning purposes.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

66

SEBU9064

Maintenance Recommendations

Engine Air Cleaner Element (Single Element) - Inspect/Clean/Replace

Pressurized air can be used to clean primary air

cleaner elements that have not been cleaned more

than three times. Use filtered, dry air with a maximum

pressure of 207 kPa (30 psi). Pressurized air will not

remove deposits of carbon and oil.

Inspecting the Primary Air Cleaner

Elements

Illustration 36

g00281693

Illustration 35

g00281692

Inspect the clean, dry primary air cleaner element.

Use a 60 W blue light in a dark room or in a similar

facility. Place the blue light in the primary air cleaner

element. Rotate the primary air cleaner element.

Inspect the primary air cleaner element for tears and/

or holes. Inspect the primary air cleaner element for

light that may show through the filter material. If it is

necessary in order to confirm the result, compare the

primary air cleaner element to a new primary air

cleaner element that has the same part number.

Note: When the primary air cleaner elements are

cleaned, always begin with the clean side (inside) in

order to force dirt particles toward the dirty side

(outside).

Aim the air hose so that air flows along the length of

the filter. Follow the direction of the paper pleats in

order to prevent damage to the pleats. Do not aim the

air directly at the face of the paper pleats.

Do not use a primary air cleaner element that has any

tears and/or holes in the filter material. Do not use a

primary air cleaner element with damaged pleats,

gaskets, or seals. Discard damaged primary air

cleaner elements.

Note: Refer to “Inspecting the Primary Air Cleaner

Elements”.

Vacuum Cleaning

Vacuum cleaning is a good method for removing

accumulated dirt from the dirty side (outside) of a

primary air cleaner element. Vacuum cleaning is

especially useful for cleaning primary air cleaner

elements which require daily cleaning because of a

dry, dusty environment.

i04150591

Engine Air Cleaner Element

(Single Element) - Inspect/

Clean/Replace

Cleaning from the clean side (inside) with pressurized

air is recommended prior to vacuum cleaning the dirty

side (outside) of a primary air cleaner element.

Refer to Operation and Maintenance Manual, “Engine

Air Cleaner Service Indicator-Inspect”.

Note: Refer to “Inspecting the Primary Air Cleaner

Elements”.

NOTICE

Never run the engine without an air cleaner element

installed. Never run the engine with a damaged air

cleaner element. Do not use air cleaner elements with

damaged pleats, gaskets or seals. Dirt entering the

engine causes premature wear and damage to en-

gine components. Air cleaner elements help to pre-

vent airborne debris from entering the air inlet.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

SEBU9064

67

Maintenance Recommendations

Engine Air Cleaner Service Indicator - Inspect

• Check for ease of resetting. The service indicator

should reset in less than three pushes.

NOTICE

Never service the air cleaner element with the engine

running since this will allow dirt to enter the engine.

• Check the movement of the yellow core when the

engine is accelerated to the engine rated speed.

The yellow core should latch at the greatest

vacuum that is attained.

A wide variety of air cleaners may be installed for use

with this engine. Consult the OEM information for the

correct procedure to replace the air cleaner.

If the service indicator does not reset easily, or if the

yellow core does not latch at the greatest vacuum,

the service indicator should be replaced. If the new

service indicator will not reset, the hole for the service

indicator may be restricted.

i02335405

Engine Air Cleaner Service

Indicator - Inspect

The service indicator may need to be replaced

frequently in environments that are severely dusty.

Some engines may be equipped with a different

service indicator.

i02927289

Engine Air Precleaner - Check/

Clean

Some engines are equipped with a differential gauge

for inlet air pressure. The differential gauge for inlet

air pressure displays the difference in the pressure

that is measured before the air cleaner element and

the pressure that is measured after the air cleaner

element. As the air cleaner element becomes dirty,

the pressure differential rises. If your engine is

equipped with a different type of service indicator,

follow the OEM recommendations in order to service

the air cleaner service indicator.

The service indicator may be mounted on the air

cleaner element or in a remote location.

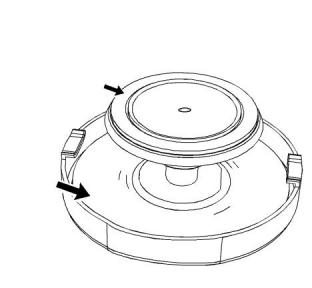

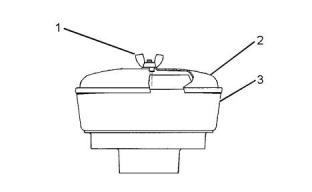

Illustration 38

g01453058

Typical engine air precleaner

(1) Wing nut

(2) Cover

(3) Body

Remove wing nut (1) and cover (2). Check for an

accumulation of dirt and debris in body (3). Clean the

body, if necessary.

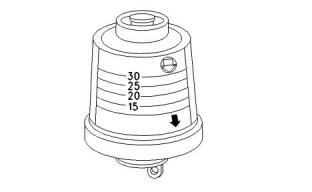

Illustration 37

g00103777

Typical service indicator

After cleaning the precleaner, install cover (2) and

wing nut (1).

Observe the service indicator. The air cleaner

element should be cleaned or the air cleaner element

should be replaced when one of the following

conditions occur:

Note: When the engine is operated in dusty

applications, more frequent cleaning is required.

• The yellow diaphragm enters the red zone.

• The red piston locks in the visible position.

Test the Service Indicator

Service indicators are important instruments.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

68

SEBU9064

Maintenance Recommendations

Engine Crankcase Breather - Replace

i05335963

NOTICE

Engine Crankcase Breather -

Replace

Make sure that the components of the breather as-

sembly are installed correctly. Engine damage may

occur if the breather assembly is not working

correctly.

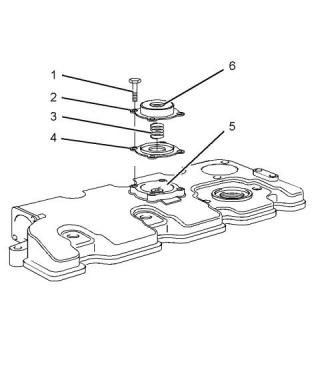

4. Install a new diaphragm and plate (4) for the

breather assembly into the cavity (5) of the valve

mechanism cover.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

5. Install a new spring (3).

6. Install the breather cover (2) and the four screws

(1). Tighten the screws.

i02323089

Engine Mounts - Inspect

Note: The engine mounts may not have been

supplied by Perkins . Refer to the OEM information

for further information on the engine mounts and the

correct bolt torque.

Inspect the engine mounts for deterioration and for

correct bolt torque. Engine vibration can be caused

by the following conditions:

• Incorrect mounting of the engine

• Deterioration of the engine mounts

• Loose engine mounts

Any engine mount that shows deterioration should be

replaced. Refer to the OEM information for the

recommended torques.

i05164949

Engine Oil Level - Check

Illustration 39

g03380583

Typical example

(1) Screws for the breather cover

(2) Breather cover

(3) Spring

(4) Diaphragm and plate

(5) Cavity

(6) Vent hole

Hot oil and hot components can cause personal

injury. Do not allow hot oil or hot components to

contact the skin.

1. Loosen the screws (1) and remove the breather

cover (2) from the valve mechanism cover.

2. Remove the spring (3). Remove the diaphragm

and plate (4).

3. Clean the vent hole (6) and the cavity (5) in the

valve mechanism cover.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

SEBU9064

69

Maintenance Recommendations

Engine Oil and Filter - Change

i05336039

Engine Oil and Filter - Change

Hot oil and hot components can cause personal

injury. Do not allow hot oil or hot components to

contact the skin.

NOTICE

Care must be taken to ensure that fluids are con-

tained during performance of inspection, mainte-

nance, testing, adjusting and repair of the product. Be

prepared to collect the fluid with suitable containers

before opening any compartment or disassembling

any component containing fluids.

Dispose of all fluids according to local regulations and

mandates.

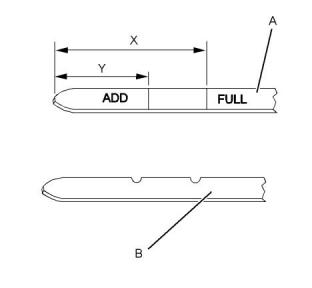

Illustration 40

g03317856

(Y) “ADD” mark. (X) “FULL” mark.

(A) Original oil level gauge

(B) Alternative oil level gauge

NOTICE

Keep all parts clean from contaminants.

NOTICE

Perform this maintenance with the engine stopped.

Contaminants may cause rapid wear and shortened

component life.

Do not drain the oil when the engine is cold. As the oil

cools, suspended waste particles settle on the bottom

of the oil pan. The waste particles are not removed

with the draining cold oil. Drain the crankcase with the

engine stopped. Drain the crankcase with the oil

warm. This draining method allows the waste

particles that are suspended in the oil to be drained

correctly.

Note: Oil gauge (A) or oil gauge (B) may be installed

in the engine.

1. Maintain the oil level between “ADD” mark (Y) and

“FULL” mark (X) on oil level gauge (1). Do not fill

the crankcase above “FULL” mark (X).

NOTICE

Failure to follow this recommended procedure will

cause the waste particles to be recirculated through

the engine lubrication system with the new oil.

Operating your engine when the oil level is above the

“FULL” mark could cause your crankshaft to dip into

the oil. The air bubbles created from the crankshaft

dipping into the oil reduces the oil's lubricating char-

acteristics and could result in the loss of power.

Drain the Engine Oil

After the engine has been run at the normal operating

temperature, stop the engine. Use one of the

following methods to drain the engine crankcase oil:

2. Remove the oil filler cap and add oil, if necessary.

Clean the oil filler cap. Install the oil filler cap.

• If the engine is equipped with a drain valve, turn

the drain valve knob counterclockwise in order to

drain the oil. After the oil has drained, turn the

drain valve knob clockwise in order to close the

drain valve.

• If the engine is not equipped with a drain valve,

remove the oil drain plug in order to allow the oil to

drain. After the oil has drained, the oil drain plug

should be cleaned and installed.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

70

SEBU9064

Maintenance Recommendations

Engine Oil and Filter - Change

Replace the Oil Filter

NOTICE

Perkins oil filters are built to Perkins specifications.

Use of an oil filter not recommended by Perkins

could result in severe engine damage to the engine

bearings, crankshaft, etc., as a result of the larger

waste particles from unfiltered oil entering the engine

lubricating system. Only use oil filters recommended

by Perkins .

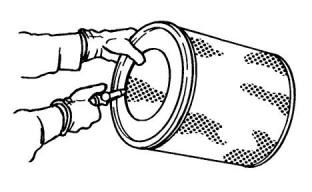

1. Remove the oil filter with a suitable tool.

Note: The following actions can be carried out as part

of the preventive maintenance program.

2. Cut the oil filter open with a suitable tool. Break

apart the pleats and inspect the oil filter for metal

debris. An excessive amount of metal debris in the

oil filter may indicate early wear or a pending

failure.

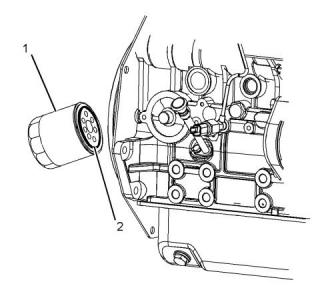

Illustration 41

g03380736

Use a magnet to differentiate between the ferrous

metals and the nonferrous metals that are found in

the oil filter element. Ferrous metals may indicate

wear on the steel and cast iron parts of the engine.

Typical example

3. Clean the sealing surface of the cylinder block.

4. Apply clean engine oil to the new O ring seal (2).

Nonferrous metals may indicate wear on the

aluminum parts, brass parts, or bronze parts of the

engine. Parts that may be affected include the

following items: main bearings, rod bearings,

turbocharger bearings and cylinder heads.

NOTICE

Do not fill the oil filters with oil before installing them.

This oil would not be filtered and could be contami-

nated. Contaminated oil can cause accelerated wear

to engine components.

Due to normal wear and friction, it is not

uncommon to find small amounts of debris in the

oil filter. Consult your Perkins dealer or your

Perkins distributor in order to arrange for a further

analysis if an excessive amount of debris is found

in the oil filter.

5. Install the new oil filter (1) Spin on the oil filter until

the O ring seal contacts the oil filter base. Rotate

the oil filter ¾ of a full turn.

Fill the Engine Crankcase

1. Remove the oil filler cap. Refer to the Operation

and Maintenance Manual for more information on

lubricant specifications. Fill the crankcase with the

correct amount of oil. Refer to the Operation and

Maintenance Manual for more information on refill

capacities.

NOTICE

If equipped with an auxiliary oil filter system or a re-

mote oil filter system, follow the OEM or filter manu-

facturer's recommendations. Under filling or overfilling

the crankcase with oil can cause engine damage.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

SEBU9064

71

Maintenance Recommendations

Engine Valve Lash - Check

NOTICE

NOTICE

To prevent crankshaft bearing damage, crank the en-

gine with the fuel OFF. This will fill the oil filters before

starting the engine. Do not crank the engine for more

than 30 seconds.

Only qualified service personnel should perform this

maintenance. Refer to the Service Manual or your au-

thorized Perkins dealer or your Perkins

distributor

for the complete valve lash adjustment procedure.

Operation of Perkins engines with incorrect valve

lash can reduce engine efficiency, and also reduce

engine component life.

2. Start the engine and run the engine at “LOW IDLE”

for 2 minutes. Perform this procedure in order to

ensure that the lubrication system has oil and that

the oil filters are filled. Inspect the oil filter for oil

leaks.

3. Stop the engine and allow the oil to drain back to

the sump for a minimum of 10 minutes.

Ensure that the engine can not be started while

this maintenance is being performed. To help pre-

vent possible injury, do not use the starting motor

to turn the flywheel.

Hot engine components can cause burns. Allow

additional time for the engine to cool before meas-

uring/adjusting valve lash clearance.

Ensure that the engine is stopped before measuring

the valve lash. The engine valve lash can be

inspected and adjusted when the temperature of the

engine is hot or cold.

Refer to Systems Operation, Testing and Adjusting,

“Engine Valve Lash - Inspect/Adjust” for more

information.

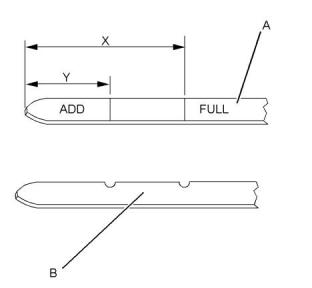

Illustration 42

g03306420

(Y) “ADD” mark. (X) “FULL” mark.

(A) Original oil level gauge

(B) Alternative oil level gauge

4. Remove the oil level gauge in order to check the oil

level. Maintain the oil level between the “ADD”

and “FULL” marks on the oil level gauge.

i05153520

Engine Valve Lash - Check

This maintenance is recommended by Perkins as

part of a lubrication and preventive maintenance

schedule in order to help provide maximum engine

life. The maintenance for the valve lash is important in

order to keep the engine compliant.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

72

SEBU9064

Maintenance Recommendations

Fan Clearance - Check

i05153591

i05161054

Fan Clearance - Check

Fuel Filter (In-Line)- Replace

Fuel leaked or spilled onto hot surfaces or electri-

cal components can cause a fire. To help prevent

possible injury, turn the start switch off when

changing fuel filters or water separator elements.

Clean up fuel spills immediately.

Note: Refer to Systems Operation, Testing, and

Adjusting, “Cleanliness of Fuel System

Components” for detailed information on the

standards of cleanliness that must be observed

during ALL work on the fuel system.

NOTICE

Ensure that the engine is stopped before any servic-

ing or repair is performed.

The location of the in-line fuel filter will depend on the

application that the engine has been installed.

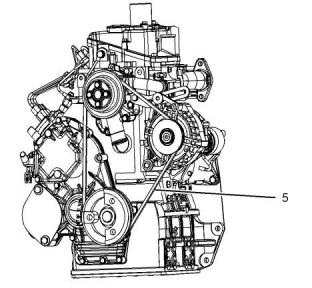

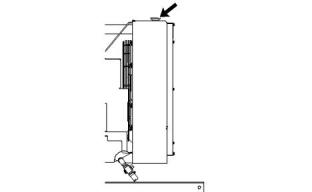

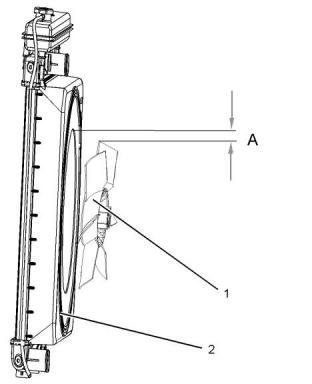

Illustration 43

g03309719

Typical example

Ensure that the engine is stopped. Ensure that the

battery disconnect switch is in the OFF position.

Ensure that the cooling system is full.

The clearance between the cover (2) and the fan (1)

will require checking. The gap between the edge of

the cover and the tip of the fan blade (A) must be

checked in four equally spaced positions.

• (A) equals 5 mm (0.19685 inch) for the three

cylinder engine and the four cylinder naturally

aspirated engine.

• (A) equals 10 mm (0.39370 inch) for the

turbocharged engine.

Illustration 44

g03315616

Arrows show fuel flow

Note: The cover is not adjustable.

Note: The in-line fuel filter is an off engine part.

1. Turn the fuel supply valve (if equipped) to the OFF

position. Remove clamp (3) and remove clamp (6).

2. Remove inlet hose (4) and remove outlet hose (5)

from in-line filter (1).

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

SEBU9064

73

Maintenance Recommendations

Fuel Injector - Test/Change

3. If installed, remove clamp (2) and remove in-line

filter (1) from application.

• The engine will not start or the engine is difficult to

start.

• Not enough power

4. Install new in-line filter (1) and install clamp (2).

• The engine misfires or the engine runs erratically.

• High fuel consumption

5. Install inlet hose (4) and install clamp (3). Install

outlet hose (5) and install clamp (6).

6. Turn the fuel supply valve (if equipped) to the ON

position. Prime the system, refer to this Operation

and Maintenance Manual, “Fuel System - Prime”.

• Black exhaust smoke

• The engine knocks or there is vibration in the

engine.

i02154268

• Excessive engine temperature

Fuel Injector - Test/Change

For further information on the removal and the

installation of the fuel injectors, refer to the

Disassembly and Assembly manual.

For further information on the testing of fuel injectors,

refer to the Testing and Adjusting manual.

Identificationof a suspect Fuel

Injector

Fuel leaked or spilled onto hot surfaces or electri-

cal components can cause a fire.

Work carefully around an engine that is running.

Engine parts that are hot, or parts that are mov-

ing, can cause personal injury.

Make sure that you wear eye protection at all

times during testing. When fuel injection nozzles

are tested, test fluids travel through the orifices of

the nozzle tip with high pressure. Under this

amount of pressure, the test fluid can pierce the

skin and cause serious injury to the operator. Al-

ways keep the tip of the fuel injection nozzle

pointed away from the operator and into the fuel

collector and extension.

NOTICE

If your skin comes into contact with high pressure

fuel, obtain medical assistence immediately.

NOTICE

If a fuel injector is suspected of operating outside of

normal parameters it should be removed by a quali-

fied technician. The suspect fuel injector should be

taken to an authorised agent for inspection.

NOTICE

Do not allow dirt to enter the fuel system. Thoroughly

clean the area around a fuel system component that

will be disconnected. Fit a suitable cover over discon-

nected fuel system component.

Operate the engine at a fast idle speed in order to

identify the faulty fuel injector. Individually loosen and

tighten the union nut for the high pressure pipe to

each fuel injector. Do not loosen the union nut more

than half a turn. There will be little effect on the

engine speed when the union nut to the faulty fuel

injector is loosened.

Regular maintenance of the fuel injectors is

recommended by Perkins . The fuel injectors must be

removed and tested by an authorized agent. The fuel

injectors should not be cleaned as cleaning with

incorrect tools can damage the nozzle. The fuel

injectors should be renewed only if a fault with the

fuel injectors occurs. Some of the problems that may

indicate that new fuel injectors are needed are listed

below:

Consult your authorized Perkins dealer or your

Perkins distributor for further assistance.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

74

SEBU9064

Maintenance Recommendations

Fuel System - Prime

i04145953

Fuel System - Prime

Turn the keyswitch to the ON position for 2 minutes in

order to prime the fuel system. Turn keyswitch to OFF

position, then turn on again. The engine is primed

and ready to start.

i05337705

Fuel System Primary Filter -

Replace

Fuel leaked or spilled onto hot surfaces or electri-

cal components can cause a fire. To help prevent

possible injury, turn the start switch off when

changing fuel filters or water separator elements.

Clean up fuel spills immediately.

NOTICE

Ensure that the engine is stopped before any servic-

ing or repair is performed.

Remove the Element

1. Turn the fuel supply valve (if equipped) to the OFF

position before performing this maintenance.

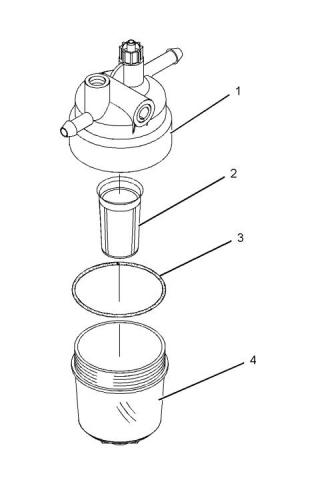

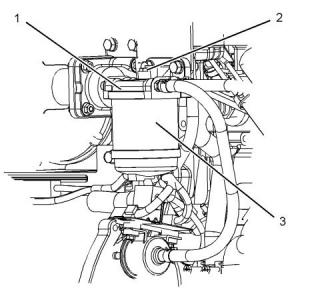

Illustration 45

g03381282

Typical example

2. Place a suitable container under the water

separator in order to catch any fuel that might spill.

Clean up any spilled fuel. Clean the outside body

of the filter assembly.

3. Remove the filter bowl (4) from the fuel filter base

(1).

4. Remove the O-ring seal (3). Discard the O-ring

seal.

5. Remove the filter element (2) from the fuel filter

base (1). Discard the filter element (2).

6. Clean the filter bowl (4).

Install the Element

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

SEBU9064

75

Maintenance Recommendations

Fuel System Primary Filter/Water Separator - Drain

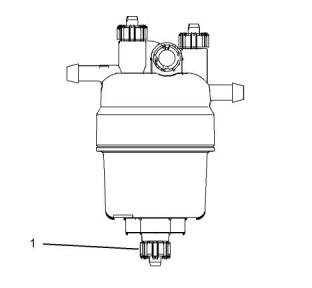

i02627223

Fuel System Primary Filter/

Water Separator - Drain

Fuel leaked or spilled onto hot surfaces or electri-

cal components can cause a fire. To help prevent

possible injury, turn the start switch off when

changing fuel filters or water separator elements.

Clean up fuel spills immediately.

NOTICE

The water separator is not a filter. The water separa-

tor separates water from the fuel. The engine should

never be allowed to run with the water separator more

than half full. Engine damage may result.

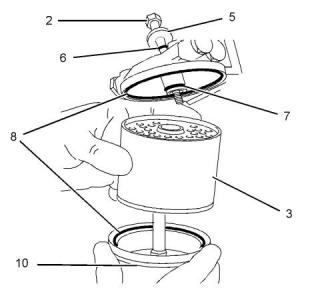

Illustration 46

g03381282

Typical example

1. Install a new filter element (2) to the fuel filter base

(1).

2. Lubricate the O ring seal (3) with clean engine oil.

Do NOT fill the bowl with fuel before the assembly

is installed.

3. Install the filter bowl (4) to the fuel filter base (1).

Illustration 47

g01316965

Tighten the filter bowl (4) by hand.

Typical example

4. The secondary fuel filter must be replaced at the

same time as the primary fuel filter. Refer to the

Operation and Maintenance Manual, “Fuel System

Secondary Filter - Replace”.

1. Open drain (1). Catch the draining fluid in a

suitable container. Dispose of the drained fluid

correctly.

2. Close drain (1).

NOTICE

The water separator is under suction during normal

engine operation. Ensure that the drain valve is tight-

ened securely to help prevent air from entering the

fuel system.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

76

SEBU9064

Maintenance Recommendations

Fuel System Secondary Filter - Replace

i05337334

Fuel System Secondary Filter -

Replace

Fuel leaked or spilled onto hot surfaces or electri-

cal components can cause a fire. To help prevent

possible injury, turn the start switch off when

changing fuel filters or water separator elements.

Clean up fuel spills immediately.

NOTICE

Do not allow dirt to enter the fuel system. Thoroughly

clean the area around a fuel system component that

will be disconnected. Fit a suitable cover over discon-

nected fuel system component.

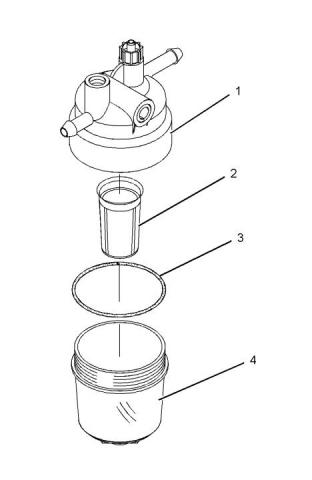

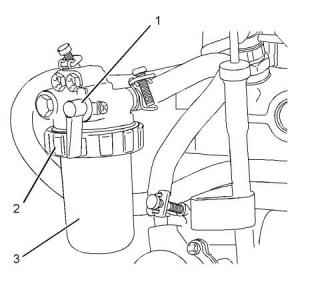

Illustration 48

g03317866

Typical example

NOTICE

Care must be taken to ensure that fluids are con-

tained during performance of inspection, mainte-

nance, testing, adjusting and repair of the product. Be

prepared to collect the fluid with suitable containers

before opening any compartment or disassembling

any component containing fluids.

2. Clean the outside of the fuel filter assembly (1).

3. Remove setscrew (2).

4. Remove the canister (3). Ensure that any fluid is

drained into a suitable container.

Dispose of all fluids according to local regulations and

mandates.

Note: The primary filter element must be replaced at

the same time as the secondary filter element. Refer

to Operation and Maintenance Manual, “Fuel System

Primary Filter (Water Separator) Element - Replace”.

Fuel Filter with Canister

1. Close the fuel supply valve.

Illustration 49

g02710378

Typical example

5. Assemble the following items: seals (8), seal (7),

canister (3) and bowl (10). Place washer (5) and

seal (6) on setscrew (2).

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

SEBU9064

77

Maintenance Recommendations

Fuel System Secondary Filter - Replace

6. Fasten the assembly to the fuel filter base with

setscrew (2).

The fuel system will need to be primed after the new

filter is installed. Refer to this Operation and

Maintenance Manual, “Fuel System - Prime”.

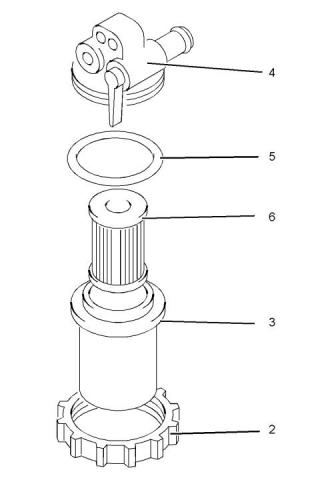

Fuel Filter with Element

1. Close the fuel supply valve (1).

Illustration 50

g01334893

Typical example

Illustration 51

g01334895

2. Clean the outside of the fuel filter assembly.

3. Loosen the locking ring (2).

Typical example

Note: Do not fill the fuel filter with fuel. The fuel will

not be filtered and the fuel could be contaminated.

Contaminated fuel can damage your fuel system.

5. Assemble the following items: seal (5), filter

element (6) and casing (3).

4. Remove the casing (3) for the filter and the

element. Ensure that any fluid is drained into a

suitable container.

6. Install the assembled items to the filter base (4).

7. Install the locking ring (2) to the filter head. Rotate

the locking ring in order to lock the assembly.

The fuel system will need to be primed after the new

filter is installed. Refer to Operation and Maintenance

Manual, “Fuel System - Prime”.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

78

SEBU9064

Maintenance Recommendations

Fuel Tank Water and Sediment - Drain

i02335436

Fuel Storage Tanks

Fuel Tank Water and Sediment

- Drain

Drain the water and the sediment from the fuel

storage tank at the following intervals:

• Weekly

• Service intervals

• Refill of the tank

NOTICE

Care must be taken to ensure that fluids are con-

tained during performance of inspection, mainte-

nance, testing, adjusting and repair of the product. Be

prepared to collect the fluid with suitable containers

before opening any compartment or disassembling

any component containing fluids.

This will help prevent water or sediment from being

pumped from the storage tank into the engine fuel

tank.

If a bulk storage tank has been refilled or moved

recently, allow adequate time for the sediment to

settle before filling the engine fuel tank. Internal

baffles in the bulk storage tank will also help trap

sediment. Filtering fuel that is pumped from the

storage tank helps to ensure the quality of the fuel.

When possible, water separators should be used.

Dispose of all fluids according to local regulations and

mandates.

Fuel Tank

Fuel quality is critical to the performance and to the

service life of the engine. Water in the fuel can cause

excessive wear to the fuel system.

i02813964

Hoses and Clamps - Inspect/

Replace

Water can be introduced into the fuel tank when the

fuel tank is being filled.

Condensation occurs during the heating and cooling

of fuel. The condensation occurs as the fuel passes

through the fuel system and the fuel returns to the

fuel tank. This causes water to accumulate in fuel

tanks. Draining the fuel tank regularly and obtaining

fuel from reliable sources can help to eliminate water

in the fuel.

Inspect all hoses for leaks that are caused by the

following conditions:

• Cracking

• Softness

Drain the Water and the Sediment

• Loose clamps

Fuel tanks should contain some provision for draining

water and draining sediment from the bottom of the

fuel tanks.

Replace hoses that are cracked or soft. Tighten any

loose clamps.

NOTICE

Open the drain valve on the bottom of the fuel tank in

order to drain the water and the sediment. Close the

drain valve.

Do not bend or strike high pressure lines. Do not in-

stall bent or damaged lines, tubes or hoses. Repair

any loose or damaged fuel and oil lines, tubes and

hoses. Leaks can cause fires. Inspect all lines, tubes

and hoses carefully. Tighten all connections to the

recommended torque. Do not clip any other item to

the high pressure lines.

Check the fuel daily. Allow five minutes after the fuel

tank has been filled before draining water and

sediment from the fuel tank.

Fill the fuel tank after operating the engine in order to

drive out moist air. This will help prevent

condensation. Do not fill the tank to the top. The fuel

expands as the fuel gets warm. The tank may

overflow.

Check for the following conditions:

• End fittings that are damaged or leaking

• Outer covering that is chafed or cut

Some fuel tanks use supply pipes that allow water

and sediment to settle below the end of the fuel

supply pipe. Some fuel tanks use supply lines that

take fuel directly from the bottom of the tank. If the

engine is equipped with this system, regular

• Exposed wire that is used for reinforcement

• Outer covering that is ballooning locally

• Flexible part of the hose that is kinked or crushed

• Armoring that is embedded in the outer covering

maintenance of the fuel system filter is important.

This document is printed from SPI². Not for RESALE

![]()

![]()

![]()

![]()

![]()

SEBU9064

79

Maintenance Recommendations

Radiator - Clean

A constant torque hose clamp can be used in place of

any standard hose clamp. Ensure that the constant

torque hose clamp is the same size as the standard

clamp.

Note: For the correct coolant, see this Operation and

Maintenance Manual, “Fluid Recommendations”.

8. Refill the cooling system. Refer to the OEM

information for further information on refilling the

cooling system.

Due to extreme temperature changes, the hose will

harden. Hardening of the hoses will cause hose

clamps to loosen. This can result in leaks. A constant

torque hose clamp will help to prevent loose hose

clamps.

9. Clean the cooling system filler cap. Inspect the

cooling system filler cap's seals. Replace the

cooling system filler cap if the seals are damaged.

Install the, cooling system filler cap.

Each installation application can be different. The

differences depend on the following factors:

10. Start the engine. Inspect the cooling system for

leaks.

• Type of hose

• Type of fitting material

i02335774

• Anticipated expansion and contraction of the hose

Radiator - Clean

• Anticipated expansion and contraction of the

fittings

The radiator is not usually supplied by Perkins . The

following text describes a typical cleaning procedure

for the radiator. Refer to the OEM information for

further information on cleaning the radiator.

Replace the Hoses and the Clamps

Refer to the OEM information for further information

on removing and replacing fuel hoses (if equipped).

Note: Adjust the frequency of cleaning according to

The coolant system and the hoses for the coolant

system are not usually supplied by Perkins . The

following text describes a typical method of replacing

coolant hoses. Refer to the OEM information for

further information on the coolant system and the

hoses for the coolant system.

the effects of the operating environment.

Inspect the radiator for these items: Damaged fins,

corrosion, dirt, grease, insects, leaves, oil and other

debris. Clean the radiator, if necessary.

Personal injury can result from air pressure.

Pressurized System: Hot coolant can cause seri-